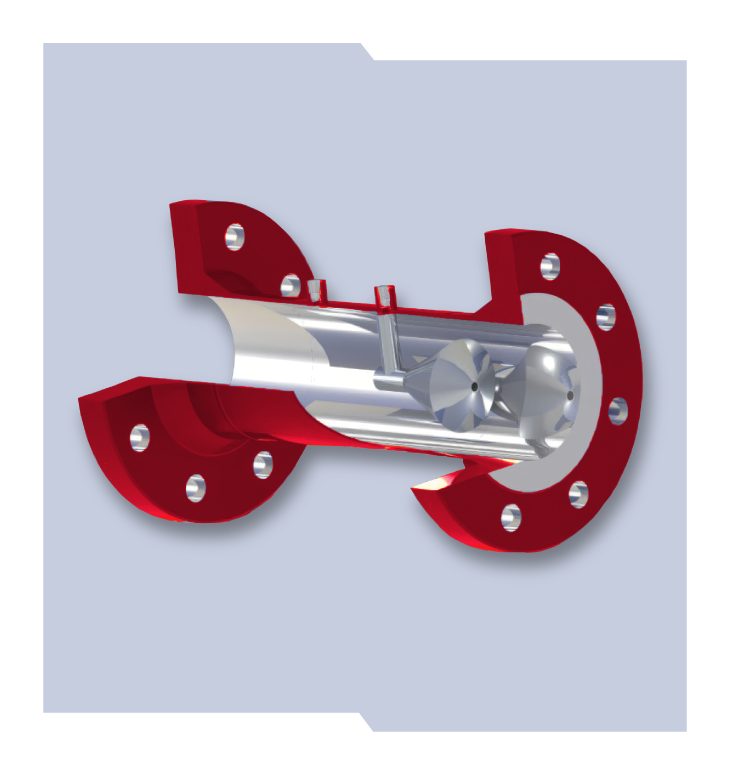

Differential Pressure Cone Meter

Accurate, Reliable, and Designed for Versatility

The Daniel® Cone Meter is a high-performance differential pressure (DP) meter designed to provide precise and repeatable flow measurement across a wide range of applications. Engineered for versatility, this meter excels in industries such as oil and gas, petrochemicals, power generation, and more. With its innovative cone design, the Cone Meter offers a reliable solution for challenging measurement conditions, including gas, liquid, and steam flows.

Coming Soon:

| Standard Accuracy | ± 0.5% to ± 5.0% of actual flow. Flow Lab calibration may be required to achieve the lowest possible accuracy. |

| Flow Ranges (turndown) | 10:1 or greater |

| Repeatability | ± 0.1% or better |

| Permanent Pressure Loss | Varies with dP and Beta Ratio |

| Beta Ratio | 0.4, 0.5, 0.6, 0.7, 0.8 (special betas available) |

| Line Sizes | 2″ to 24″ – 26″ and above – Series “A” & “B” ANSI 150 thru 600 |

| Pressure Ratings | ANSI 150 thru 2500 |

| Construction Materials | All Grades of Stainless Steel, Carbon Steel and Alloys or any other weldable material. |

| End Configuration | Beveled, Flanged, Threaded, hubs, and others. |

| Approvals | CE-PED 2014/68/EU, CRN |

- Standard accuracy ranges from ±0.5% to ±5.0% of actual flow, with flow lab calibration available for the highest accuracy.

- Capable of flow ranges with a 10:1 turndown or greater, providing versatility for various applications.

- Choose from a wide range of beta ratios (0.4 to 0.8), ensuring the right configuration for your system.

- Available in all grades of stainless steel, duplex steel, carbon steel, and other materials to meet your specific operational requirements.

- End connections include beveled, flanged, threaded, hubs, and more to suit your installation needs.

- The Cone Meter has no moving parts, minimizing maintenance requirements, and ensuring long-term reliability.

- Delivers consistent repeatability of ±0.1% or better, ensuring accurate measurements over time.

- Tailor the meter to your specific system requirements with customized materials and configurations, all built to ISO standards.

- Designed to minimize pressure loss, improve energy efficiency, and lower operating costs.

| Line Size | DN50 to DN200 (2-in to 8-in) |

| Fluid Type | Liquid |

| Operating Temperature Range | -29º C to +66º C (-20º F to +150º F) |

| Operating Pressure Range | ANSI 150 to 300 |

| Materials: Valve Body | Carbon Steel, ASTM A352 GR LCC |

| Materials: Valve Cylinder | DN50 to DN 200 (2-in to 4-in): Stainless Steel, ANSI 150 to 600; DN250 to DN 300 (6-in to 8-in) Carbon Steel, Nickel Coated, ANSI 150 to 600 |

| Materials: Valve Piston | Standard: Stainless Steel |

| Materials: Seat Ring | DN50 to DN200 (2-in to 6-in) Stainless Steel; DN300 (8-in) Carbon Steel, Nickel Coated |

| Materials: O-Rings | Standard: Viton; Optional: Neoprene, EPR, Kalrez / Teflon AP (Aggressive Products) |