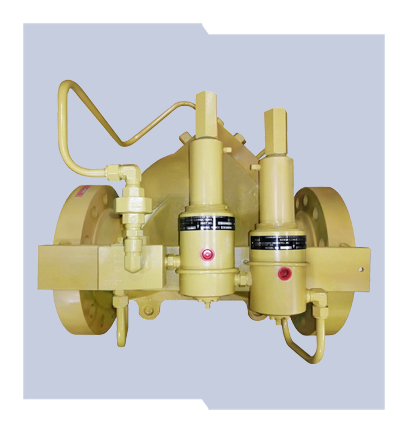

Series 700 External Pilot Operated Liquid Control Valves

Precise Flow Control of Petroleum Products

Precisely control the flow of liquid petroleum products with Daniel® Series 700 External Pilot Operated Control Valves that ensure positive sealing, smooth linear action and uniform speed of response. This versatile, cost-effective line enables a single valve body to be equipped with a variety of external pilots, allowing one valve to serve multiple functions. Unit-built construction allows all internal parts to be removed without interfering with the valve body or connections, simplifying maintenance and maximizing uptime.

Coming Soon:

| Line Size | DN50 to DN400 (2-in to 16-in) |

| Fluid Type | Liquid |

| Operating Temperature Range | -29º C to +66º C (-20º F to +150º F) |

| Operating Pressure Range | ANSI 150 to 600 |

| Materials of Construction | • Valve Body: Carbon Steel, ASTM A352 GR LCC • Valve Cylinder: DN50 to DN 200 (2-in to 4-in): Stainless Steel, ANSI 150 to 600; DN250 to DN 400 (6-in to 16-in) Carbon Steel, Nickel Coated, ANSI 150 to 600 • Valve Piston: Standard: Stainless Steel |

| Materials of Construction | • Seat Ring: DN50 to DN200 (2-in to 6-in) Stainless Steel; DN300 to DN400 (8-in to 16-in) Carbon Steel, Nickel Coated • O-Rings: Standard: Viton; Optional: Neoprene, EPR, Viton, all Buna-N, Kalrez / Teflon AP (Aggressive Products) |

- Achieve precise flow rate and batch control with high-performance balanced piston principle, spring-biased design

- Avoid damage due to shock pressure by adjusting closing speed; main piston ensures uniform opening and closing

- Ensure smooth linear action with maximum flow and minimum pressure drop with high-capacity, 45º valve body

- Control pressure from 10 to 1440 psi (60 to 9928 kPa) within ±2 psi (±13.8 kPa) of setpoint

- Safeguard equipment and personnel with positive shutoff (ANSI Class VI) and fail-safe closure upon power loss

- Improve reliability with positive O-ring seal and valve seats that are unaffected by fluid viscosity or pressure drop

- Maximize uptime with all internal parts housed in a cartridge assembly; no need to remove the valve from the line

- Minimize wear-related maintenance with a simple design featuring no diaphragms or stuffing boxes

Downloadable PDF

| Line Size | DN50 to DN200 (2-in to 8-in) |

| Fluid Type | Liquid |

| Operating Temperature Range | -29º C to +66º C (-20º F to +150º F) |

| Operating Pressure Range | ANSI 150 to 300 |

| Materials: Valve Body | Carbon Steel, ASTM A352 GR LCC |

| Materials: Valve Cylinder | DN50 to DN 200 (2-in to 4-in): Stainless Steel, ANSI 150 to 600; DN250 to DN 300 (6-in to 8-in) Carbon Steel, Nickel Coated, ANSI 150 to 600 |

| Materials: Valve Piston | Standard: Stainless Steel |

| Materials: Seat Ring | DN50 to DN200 (2-in to 6-in) Stainless Steel; DN300 (8-in) Carbon Steel, Nickel Coated |

| Materials: O-Rings | Standard: Viton; Optional: Neoprene, EPR, Kalrez / Teflon AP (Aggressive Products) |