Flow Nozzle

Versatile, Accurate, and Designed for High-Pressure Applications

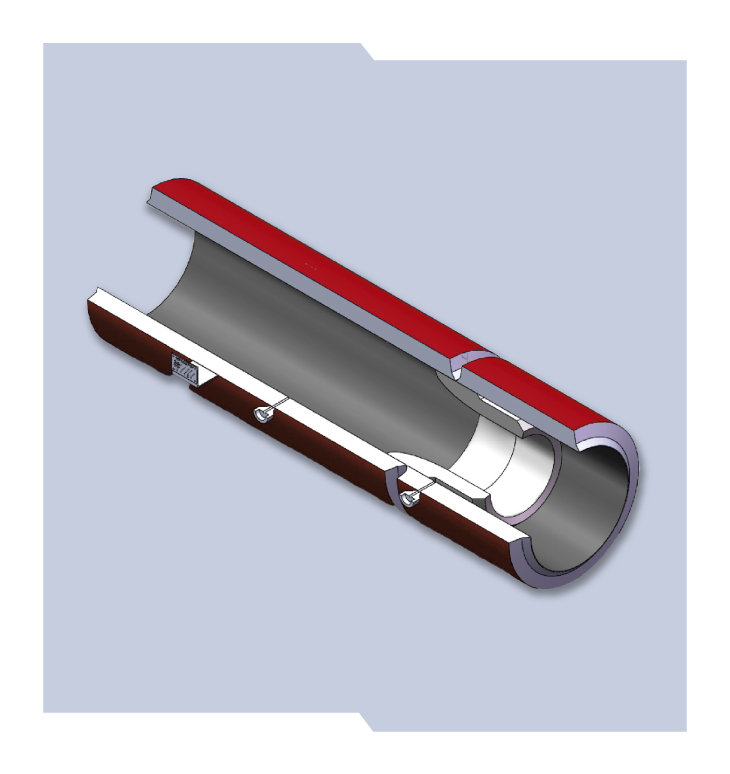

The Daniel® Flow Nozzle combines the simplicity of an orifice plate with the hydrodynamic benefits of a Venturi tube. This versatile flow meter is ideal for high-pressure, high-temperature systems where high-velocity fluids need to be measured. Commonly used in power plants, refineries, and processing facilities, the Daniel® Flow Nozzle excels in handling challenging fluids such as steam, gas, and liquids.

With its gradual, sloping profile, the Flow Nozzle provides increased flow capacity and improved accuracy compared to standard orifice plates, while maintaining a compact design that allows for easy installation between flanges.

Coming Soon:

| Standard Accuracy | 0.8% standard, 0.25% available with calibration |

| Flow Ranges (turndown) | 10:1 or greater |

| Repeatability | ± 0.1% or better |

| Permanent Pressure Loss | Varies with DP and Beta (H/D) Ratio |

| Beta Ratio | 0.4, 0.5, 0.6, 0.7; Additional betas available by request. |

| Line Sizes | 2” to 24” – 26”and larger – available in any flange specification. |

| Pressure Ratings | ANSI 150 thru 2500 |

| Construction Materials | All Grades of Stainless Steel, Carbon Steel and Alloys or any other weldable material. |

| End Configuration | Wafer, Flanged, Beveled, Threaded and Others |

| Approvals | CE-PED 2014/68/EU, CRN |

- Achieves measurement accuracy of ±0.8% with repeatability of ±0.1%, and up to 0.25% accuracy with flow lab calibration.

- Available in sizes from 2” to 24”, with larger sizes available upon request.

- Offered in flanged, tapped, weld-in, and holding ring designs to suit various applications.

- Available in stainless steel, duplex stainless, carbon steel, and other weldable materials based on system requirements.

- Provides 60% greater flow capacity than an orifice plate with the same beta ratio.

- Ideal for high-velocity fluids, delivering better accuracy as flow rates increase.

- Excels in high-pressure, high-temperature environments, making it the preferred solution for demanding applications.

| Line Size | DN50 to DN200 (2-in to 8-in) |

| Fluid Type | Liquid |

| Operating Temperature Range | -29º C to +66º C (-20º F to +150º F) |

| Operating Pressure Range | ANSI 150 to 300 |

| Materials: Valve Body | Carbon Steel, ASTM A352 GR LCC |

| Materials: Valve Cylinder | DN50 to DN 200 (2-in to 4-in): Stainless Steel, ANSI 150 to 600; DN250 to DN 300 (6-in to 8-in) Carbon Steel, Nickel Coated, ANSI 150 to 600 |

| Materials: Valve Piston | Standard: Stainless Steel |

| Materials: Seat Ring | DN50 to DN200 (2-in to 6-in) Stainless Steel; DN300 (8-in) Carbon Steel, Nickel Coated |

| Materials: O-Rings | Standard: Viton; Optional: Neoprene, EPR, Kalrez / Teflon AP (Aggressive Products) |