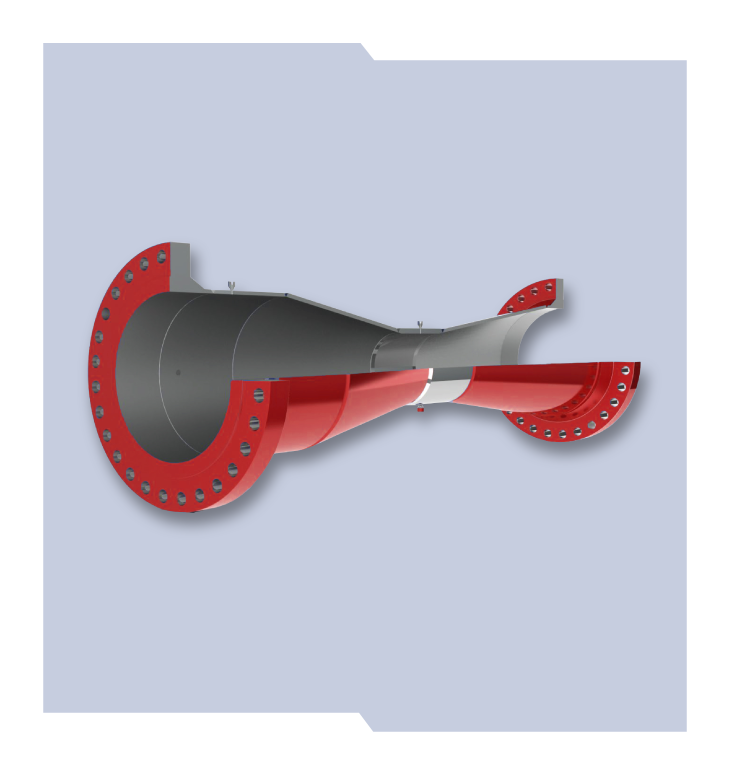

Venturi Tube

Proven, Reliable, and Low-Maintenance Flow Measurement

The Daniel® Venturi Tube is a proven and reliable solution for fluid measurement applications. Its rugged, streamlined design eliminates sharp edges or angles, making it ideal for measuring solid-laden fluids and slurries. The gradual sloping profile minimizes build-up, ensuring accurate measurements with minimal maintenance.

One of the key features of the Venturi tube is its low pressure drop, which significantly reduces pumping and operating costs—ideal for low-pressure systems requiring small differentials. Commonly used in gas, liquid, and steam measurement, Daniel® Venturi Tubes are found across various industries, including oil and gas processing, petrochemicals, power generation, and water treatment.

Coming Soon:

| Standard Accuracy | 0.5% standard, higher accuracies available with calibration |

| Flow Ranges (turndown) | 10:1 or greater |

| Repeatability | ± 0.1% or better |

| Permanent Pressure Loss | Varies with DP and Beta (H/D) Ratio |

| Beta Ratio | 0.4, 0.5, 0.6, 0.7; Additional betas available by request. |

| Line Sizes | 2” to 24” – 26”and larger – available in any flange specification. |

| Pressure Ratings | ANSI 150 thru 2500 |

| Construction Materials | All Grades of Stainless Steel, Carbon Steel and Alloys or any other weldable material. |

| End Configuration | Wafer, Flanged, Beveled, Threaded and Others |

| Approvals | CE-PED 2014/68/EU, CRN |

- Provides measurement accuracy of ±0.5% and repeatability of ±0.1%.

- Available in a wide range of pipe sizes from 2” to 24”, with larger sizes available upon request.

- Choose from flanged, threaded, beveled, or wafer options to suit your system’s needs.

- Available in stainless steel, duplex steel, carbon steel, and custom alloys to meet specific operational demands.

- Manufactured to ISO 5167-4 standards, ensuring consistent quality and performance.

- Lower pressure drop than other primary elements, reducing energy costs.

- With no moving parts, the Venturi Tube requires minimal upkeep and is resistant to wear.

- Capable of measuring gas, liquid, and steam across a wide range of industries.

- Designed to withstand extreme pressures and temperatures, making it ideal for demanding environments.

| Line Size | DN50 to DN200 (2-in to 8-in) |

| Fluid Type | Liquid |

| Operating Temperature Range | -29º C to +66º C (-20º F to +150º F) |

| Operating Pressure Range | ANSI 150 to 300 |

| Materials: Valve Body | Carbon Steel, ASTM A352 GR LCC |

| Materials: Valve Cylinder | DN50 to DN 200 (2-in to 4-in): Stainless Steel, ANSI 150 to 600; DN250 to DN 300 (6-in to 8-in) Carbon Steel, Nickel Coated, ANSI 150 to 600 |

| Materials: Valve Piston | Standard: Stainless Steel |

| Materials: Seat Ring | DN50 to DN200 (2-in to 6-in) Stainless Steel; DN300 (8-in) Carbon Steel, Nickel Coated |

| Materials: O-Rings | Standard: Viton; Optional: Neoprene, EPR, Kalrez / Teflon AP (Aggressive Products) |