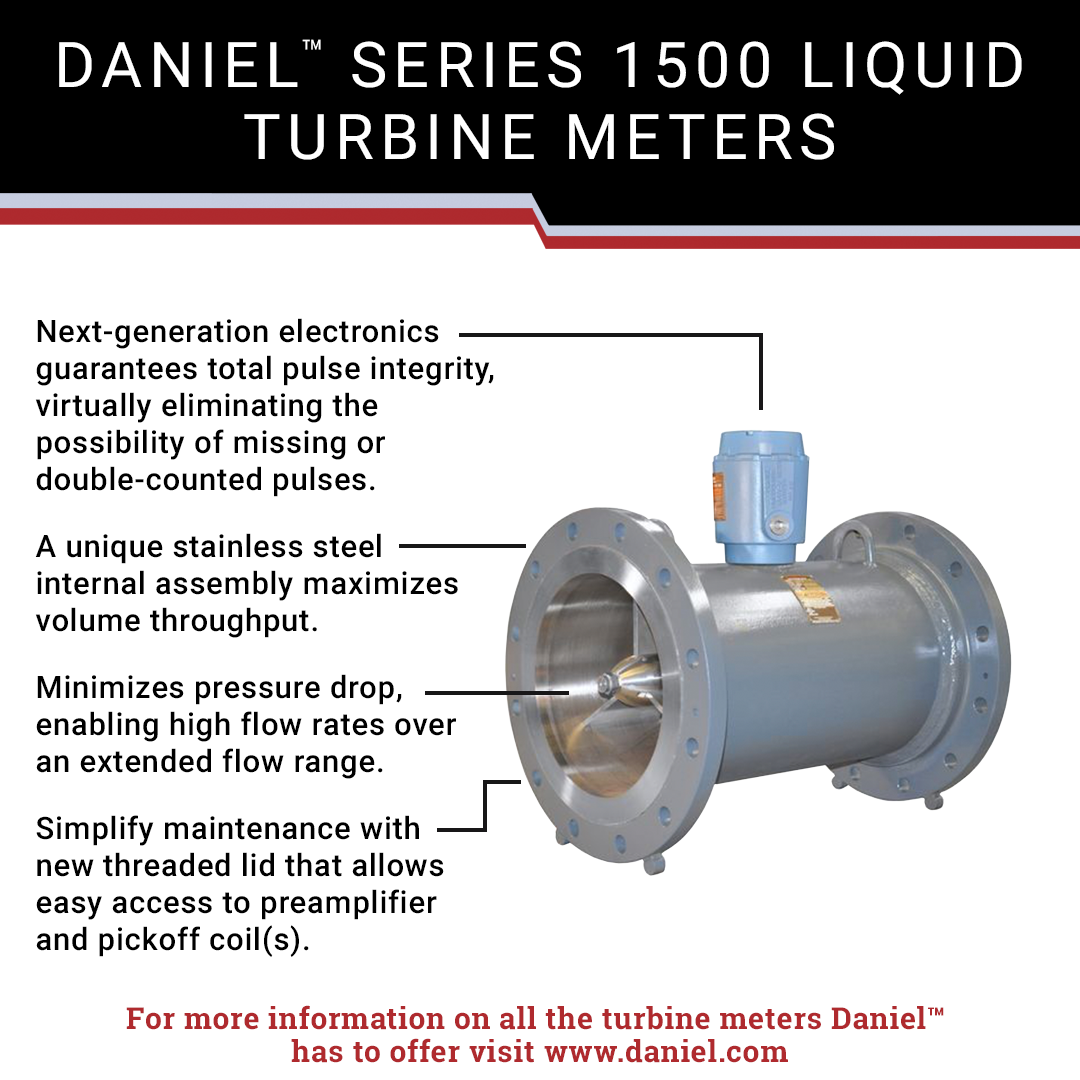

Daniel™ Series 1500 Liquid Turbine Meters

Custody Transfer Reliability

A turbine flow meter is used for volumetric total flow and/or flow rate measurement and has a relatively simple working principle. As fluid flows through the turbine meter, it impacts turbine blades that are free to rotate about an axis along the center line of the turbine housing. The angular (rotational) velocity of the turbine rotor is directly proportional to the fluid velocity flowing through the turbine. The resulting output is taken by an electrical pickoff(s) mounted on the flow meter body. Liquid turbine meters serve a variety of hydrocarbon applications, including fiscal and custody transfer, check metering, or blending/batching. The flow meters are often installed for measurement during crude oil production, tank farm/storage inventory control, floating production, storage and offloading (FPSO), as well as refined product loading and offloading. The repeatability of the meters ensures quality measurement over a wide range of flow rates, temperatures, compositions, and viscosities.

Daniel offers the largest combination of line sizes, pressure classes, and materials (NACE MR0175) as standard turbine meter configurations along with the most international product approvals. Just like our Daniel™ Series 1500 Liquid Turbine Meters, we calibrate our small line size meters (1” – 8”) with mineral spirits, which provides the best combination of viscosity and specific gravity to provide an optimum response for light hydrocarbon applications on terminal operations. For more information about all the Flow and Turbine Meters Daniel has to offer